In today’s fast-paced world, businesses constantly strive for growth and success. However, despite the best efforts of managers and employees, unforeseen issues can arise that can derail even the most well-planned projects.

In such situations, it is essential to identify and fix the issue as quickly and efficiently as possible to minimize the damage and get back on track. Failure to do so can result in lost revenue, decreased productivity, and damage to the company’s reputation.

We will explore the importance of identifying issues oil leaking from air compressor in a timely manner and implementing effective solutions to resolve them. We will also explore the various strategies and techniques that can be used to fix the issue, including root cause analysis, process improvement, and change management.

Identify And Fix The Issue Oil Leaking From Air Compressor

Compressed air is a crucial component in various industrial processes. It is handy to power machines, equipment, and tools, making it an indispensable resource for many businesses. However, as with any machinery, air compressors are prone to wear and tear, and their components can fail over time. One of the most common problems associated with air compressors is oil leaking.

Oil leaks can cause serious problems, such as contamination, environmental hazards, and damage to equipment. Therefore, it is critical to identify and address oil leaks as soon as possible. Here are details to know how to identify and fix the issue oil leaking from air compressor.

Step 1: Safety Precautions

When dealing with oil leaking from an air compressor, you should consider safety precautions. The first step is to ensure the air compressor is turned off and unplugged from any power source. This will prevent any accidents from happening while you work on the machine. Next, you should wear protective gear such as gloves and safety glasses to avoid any contact with the oil.

The oil can harm your skin and eyes, so it is important to take the necessary precautions. Once you have taken these safety measures, you can begin to assess the situation and determine the cause of the leak. It is important to fix the issue as soon as possible to prevent further damage to the machine or potential hazards in the workplace.

Step 2: Identify The Source Of The Leak

The oil leaking from the air compressor could have multiple sources, and it’s essential to identify the exact location to prevent further damage and ensure safe operation. One possible cause of the oil leak could be a defective oil seal that needs to be replaced. Another common reason for oil leaks is a cracked or damaged valve cover gasket. A damaged piston ring or cylinder wall could also cause oil to leak from the air compressor.

A careful inspection of the air compressor’s components can help identify the source of the leak. The first step is to check the oil level and determine if it’s low or contaminated with dirt or debris. Next, inspect the valve cover and surrounding areas for signs of oil leaks. Check the compressor’s hoses, fittings, and seals for visible damage or wear.

Step 3: Drain The Oil

The air compressor had been working perfectly fine until it started leaking oil one day. The operator immediately realized that if the issue was not addressed immediately, it could cause serious damage to the machine. He knew he had to drain the oil from the compressor to prevent further damage. The task was not easy, as the compressor was large and heavy, but he knew it was essential.

He removed the oil drain plug and let the compressor drain all the oil into a container. The thick black oil indicated that it had not changed in a long time. He drained all the oil and checked the oil filter, finding it clogged with debris. He replaced the oil filter and filled the compressor with fresh oil. The compressor was now running smoothly, without any leaks or issues.

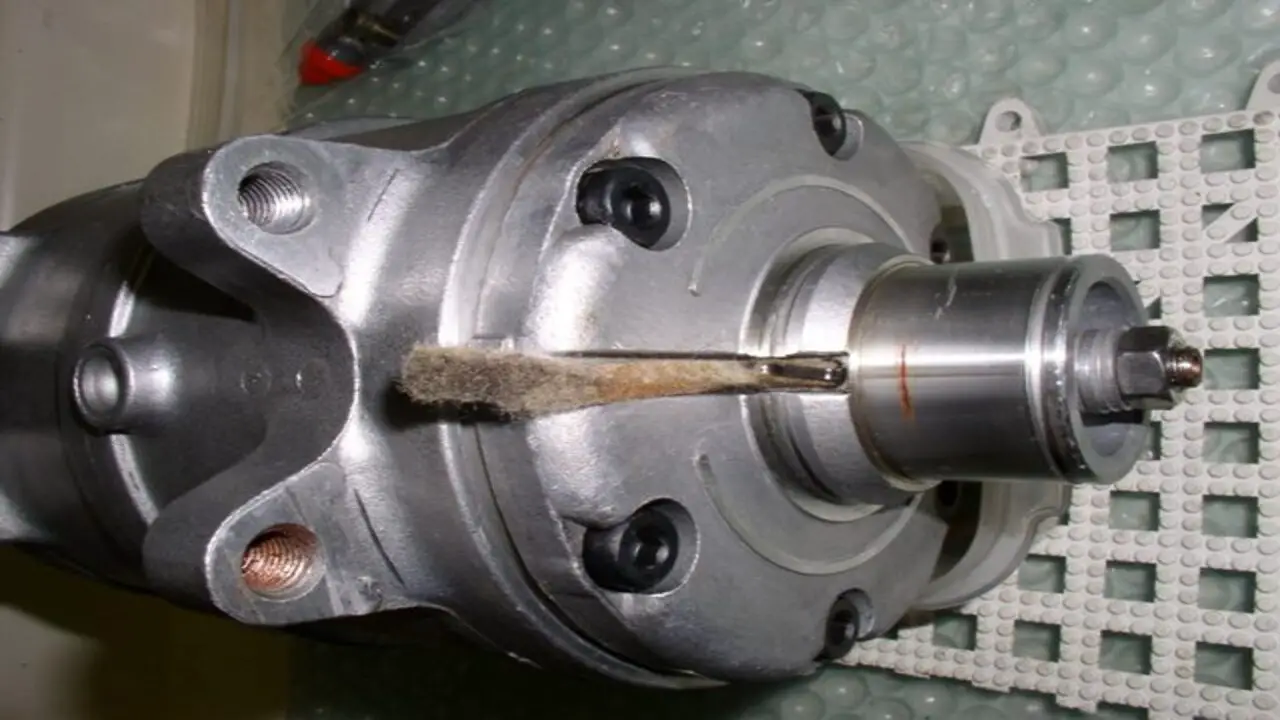

Step 4: Replace Gaskets And Seals

If you have noticed oil leaking from your air compressor, it could be due to worn-out gaskets and seals. Over time, these components can degrade and fail, leading to oil leaks and decreased compressor efficiency. To prevent further damage to your compressor, it is essential to promptly replace the gaskets and seals. Replacing gaskets and seals is a relatively straightforward process that can do with a few basic tools. First, locate the faulty gasket or seal and remove it from the compressor.

You can then install a new gasket or seal in its place, ensuring you securely position it. Finally, you will need to test the compressor to ensure that it is functioning correctly and that there are no more oil leaks. By replacing your compressor’s gaskets and seals, you can prevent further damage to the unit and extend its lifespan.

Step 5: Tighten Loose Connections

If you have noticed oil leaking from your air compressor, it could be due to worn-out gaskets and seals. Over time, these components can degrade and fail, leading to oil leaks and decreased compressor efficiency. To prevent further damage to your compressor, it is essential to promptly replace the gaskets and seals. You can replace gaskets and seals with a few basic tools because it is relatively straightforward.

First, locate the faulty gasket or seal and remove it from the compressor. You can then install a new gasket or seal in its place, ensuring that you securely position it. Finally, you will need to test the compressor to ensure that it is functioning correctly and that there are no more oil leaks. By replacing your compressor’s gaskets and seals, you can prevent further damage to the unit and extend its lifespan.

Step 6: Inspect The Oil Fill Cap

If you’ve noticed oil leaking from your air compressor, it’s important to inspect the oil fill cap. The oil fill cap is a critical component that ensures that the oil stays inside the compressor and doesn’t leak out. Over time, the oil fill cap can become loose or damaged, which can cause oil to leak out of the compressor.

To inspect the oil fill cap, turn off the compressor and unplug it from the power source. Next, locate the oil fill cap on the compressor and carefully remove it. Check the cap for any signs of damage, such as cracks or wear, and ensure it’s seated properly. It must be replaced if the cap is damaged or not seated correctly.

Step 7: Refill With Oil

If you notice oil leaking from your air compressor, it is important to immediately prevent further damage and ensure that it continues functioning properly. One of the first steps is to refill the compressor with oil. This simple step can help prevent any damage caused by the lack of lubrication in your compressor.

However, it is important to identify the source of the oil leak before refilling the compressor with oil. We will help prevent further oil loss and ensure the issue is resolved. There are several possible causes of an oil leak in an air compressor, including worn or damaged seals, cracked or broken parts, or improper compressor installation.

Step 8: Test For Leaks

When it comes to air compressors, leaks can be a common occurrence. That’s why performing a test for leaks is essential. One sign that there might be a leak is oil leaking from the air compressor. A faulty seal or gasket, a loose connection, or damage to the compressor could cause this. To diagnose the issue, shut off the compressor and let it cool down. Next, inspect all connections, fittings, and hoses for signs of wear or damage.

If everything looks good, perform a soap and water test to check for leaks. Simply apply a mixture of soap and water to all connections and fittings and look for bubbles. If bubbles form, that indicates a leak. Once the source of the leak has been identified, it’s essential to address it promptly. Leaving a leak unchecked can lead to further damage to the compressor or potentially dangerous situations.

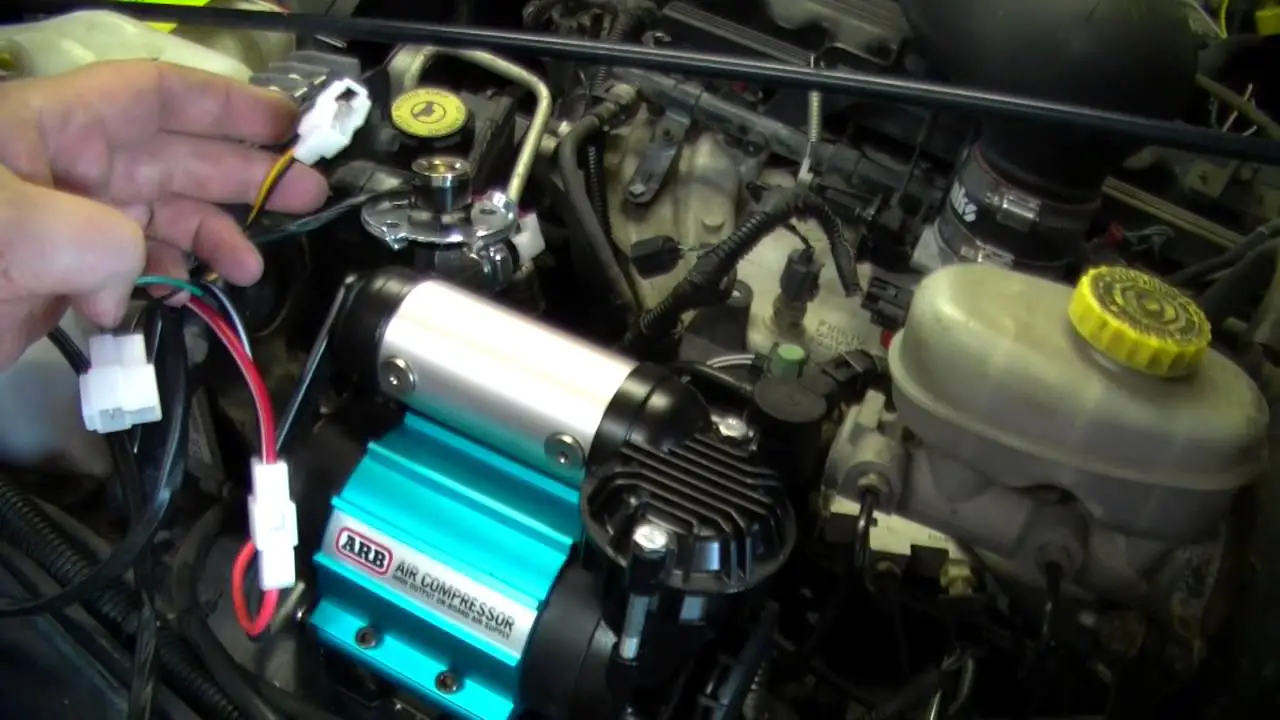

Step 9: Regular Maintenance

Regular maintenance is crucial for the efficient and safe operation of any equipment, including air compressors. Neglecting maintenance can lead to many problems, including oil leaks from the air compressor. Oil leaks are a common issue that can cause significant damage to the compressor’s internal components and surrounding equipment. If you notice oil leaking from your air compressor, it is essential to address the issue immediately.

Ignoring the problem could result in costly repairs or even replacing the compressor. To prevent oil leaks from occurring in the first place, it is vital to perform regular maintenance on your air compressor. This includes checking oil levels, replacing filters, and checking for any signs of wear and tear. Regular maintenance also ensures that all components work correctly and that the compressor runs efficiently.

Conclusion:

oil leaking from air compressor can be a common issue caused by various factors such as worn-out gaskets, damaged seals, loose connections, or overfilled oil levels. It is essential to address oil leaks promptly to prevent further damage to the compressor and ensure safe and efficient operation. While some minor leaks may be temporarily fixed with sealants, performing proper repairs by replacing damaged gaskets and seals is best.

Regular maintenance, including checking for leaks, inspecting connections, and following the manufacturer’s recommended oil change schedule, is crucial in preventing future oil leaks and maintaining the compressor’s longevity and performance.

If uncertain about the repair process or if the compressor is under warranty, seeking professional help is advisable to ensure the proper resolution of the oil leak issue. Always prioritize safety by turning off the compressor and wearing appropriate safety gear when performing any repair work.

FAQs

[rank_math_rich_snippet id=”s-58770dc8-8c84-49c0-bfb2-c8416010da62″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.