Air compressors are vital in many workshops and factories, powering tools and machines to get the job done. One of the most overlooked maintenance tasks is replacing the air filter in your compressor, which can lead to decreased performance and even damage to the machine.

Here we will guide you through easy steps on how to replace the air filter in your air compressor, from turning off the machine to installing the new filter. We’ll also discuss why it’s important to replace your air compressor filter regularly and what happens if you don’t. Additionally, we’ll cover common contaminants that affect your compressor and whether portable or inlet air compressor filters are right for you.

What Is An Air Compressor Filter?

An air compressor filter is designed to remove contaminants such as dirt, dust, and oil from the air that enters the compressor. These contaminants can cause damage to the compressor’s components over time, leading to decreased performance and even failure. That’s why it’s crucial to replace your air filter on a regular basis.

How To Replace The Air Filter In Your Air Compressor – 4 Easy Steps

Replacing the air filter in your compressor can be done easily by following simple steps. Start by turning off and unplugging your compressor to ensure your safety. Next, locate and remove the air filter from its housing. Clean the area around it to prevent debris entering your compressed air system.

Install a new filter element properly to maintain clean filters regularly for optimal performance. Reconnect any hoses that were removed during the process. Lastly, turn on your compressor to check for proper airflow and performance. Here are some details steps on how to replace the air filter in your air compressor below:

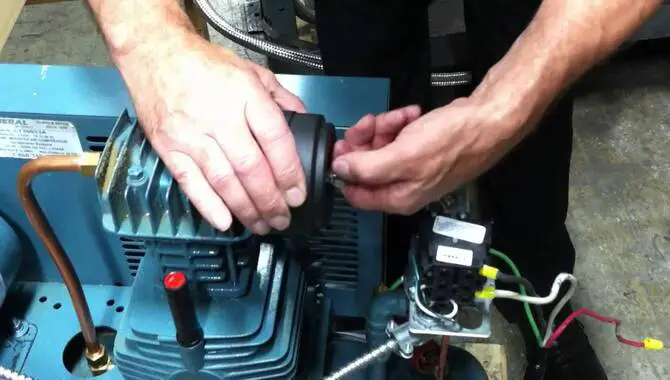

1. Turning Off The Compressor And Locating The Filter

When looking to replace your air compressor’s air filter, always consult the manufacturer’s instruction guide to find its precise location. Your compressor’s intake valve or side is typically where you’ll find it.

To avoid damaging your machinery or making poor-quality compressed air due to particulate contaminants and pressure drops caused by dirty filters, shut off your equipment first and let it cool down before handling it.

Remove all clips or screws from old filters if necessary before checking for debris and corrosion that could cause issues in airflow and other moving parts of your machine.

2. Removing The Old Filter And Cleaning The Area

Before replacing an air filter in your air compressor, ensure you have turned off and unplugged the compressor. After removing the screws or clips holding the old filter in place, dispose of it properly. Use a soft cloth or brush to gently clean the area around the filter housing to remove debris and dust that could affect airflow.

If needed, replace any gaskets or seals before installing a new air filter into its proper location. Ensure that new filters are inserted securely so that there will be no leakage of compressed air from your system. Finally, reattach all screws or clips that were removed earlier before testing your air compressor for proper operation.

3. Installing The New Air Filter And Restarting The Compressor

To replace your compressor’s old air filter and guarantee satisfactory performance, start by switching off and unplugging your compressor. Then carefully unscrew your old filter from its housing, ensuring no moving parts are damaged. Clean or replace any gaskets or seals before installing a high-quality replacement filter in the proper airflow direction, as shown on its label.

Tighten all screws securely while avoiding over-tightening to prevent damaging your new air filter cap. After plugging in and restarting your system, you can enjoy clean compressed air output at regular intervals for a long time without worrying about poor performance or expensive repairs.

4. The Importance Of Replacing Your Air Compressor Filter

Regularly replacing your air compressor filter is crucial for maintaining optimal performance and extending the lifespan of your machinery. Dirty or clogged filters restrict airflow and cause pressure drops in your compressed air system resulting in poor air quality and inefficient operation.

Choosing the correct size and type of filter element is important for effective filtration per manufacturer instructions. Don’t wait until you need expensive repairs or find residue on moving parts. Regular gentle cleaning agent application intervals guarantee clean filters, ensuring a quiet zone while operating pneumatic tools and keeping energy costs low.

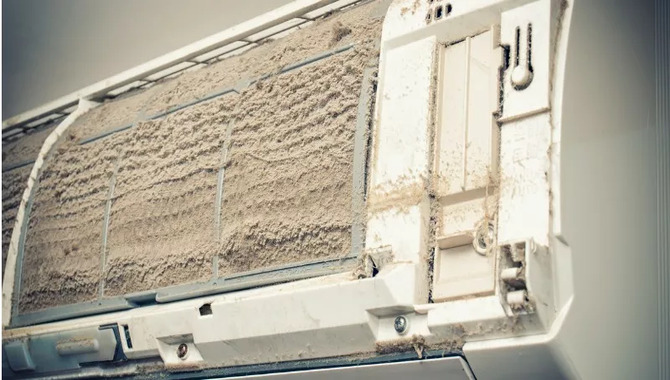

How Does A Dirty Air Filter Affect Your Compressor?

A dirty air filter can have a significant impact on the performance of your air compressor. It restricts airflow, causing pressure drop and reducing overall efficiency.

This leads to poor air quality and puts extra strain on the machinery, potentially resulting in expensive repairs or even complete failure of the system. Regularly replacing your air filter can ensure optimal performance and extend the lifespan of your equipment.

Common Contaminants That Affect Your Compressor

Contaminants such as dust and debris can accumulate in your air compressor’s air filter. Causing a reduction in efficiency, while moisture leads to rust and corrosion on the compressor’s components. To avoid poor performance or costly repairs of pneumatic tools or machinery due to dirty air filters, which cause pressure drops or moved parts to stick together ensure that you clean your filters at regular intervals.

Besides, using an inlet filtration system with a separator for humidity or oil filters for lubricant aerosol or activated carbon for vapor absorption is a good idea too. Don’t forget to gently clean the inside and outside of your compressor using clean air to save energy costs.

Portable Vs Inlet Air Compressor Filters

Choosing between portable and inlet air compressor filters is crucial for ensuring good-quality compressed air. Portable filters are disposable, while inlet ones can wash and reuse. Nonetheless, both require replacement at regular intervals to maintain peak performance.

A high-quality filtration system can keep your machinery free from residue, rust or moisture that can cause poor performance or expensive repairs later on. Go for an inlet with an oil separator or an activated carbon element in addition to a filtration system for higher efficiency.

Conclusion

Air compressor filters play a crucial role in maintaining the longevity and efficiency of your air compressor. Regularly replacing your air compressor filter is important to ensure that your compressor is functioning optimally.

Dirty air filters can impact the performance of the compressor, leading to decreased airflow, increased energy consumption, and even damage to the motor. Follow our step-by-step guide on how to replace your air compressor filter easily.

We also provide information on common contaminants that affect your compressor and discuss how to replace the air filter in your air compressor. Keep your air compressor running smoothly by replacing its filter regularly.

By following these steps, you can easily replace your air filter and ensure that your compressor operates at peak efficiency. Consult your owner’s manual for specific instructions and recommended replacement intervals.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-1f497f50-9cda-416f-9bea-4552deca2e82″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.