Air compressors are widely used in various industries, such as construction, automotive, and manufacturing. They are used to power tools and machinery that require compressed air to function properly.

Air compressor tanks are essential to these machines, as they store compressed air and regulate pressure. However, these tanks are prone to damage and require maintenance and repair to ensure they function safely and efficiently. Air compressor tank repair involves fixing any damage to the tank, such as leaks or cracks, and ensuring that it is structurally sound.

It is essential to repair any damage promptly to prevent further damage and potential safety hazards. Ignoring damage to an air compressor tank can lead to catastrophic failures, including explosions, which can cause serious injury or even death.

Repairing air compressor tanks is not only important for safety but also for efficiency. A damaged tank can cause the compressor to work harder, increasing energy consumption and decreasing productivity.

Required Tools And Materials For Tank Repair

Compressor tank repair can be dangerous and should only be attempted by individuals with the necessary skills and experience. For more complex repairs or in cases of uncertainty, it’s best to seek assistance from a professional repair service. Safety should always be a top priority when working with high-pressure vessels like air compressor tanks. To perform compressor tank repair, you’ll need the following tools and materials:

Tools:

- Safety Gear: Safety goggles, gloves, and a dust mask to protect yourself during the repair process.

- Adjustable Wrench: Used to loosen and tighten nuts and bolts on the tank.

- Socket Set: Helps with removing and replacing fasteners on the compressor.

- Screwdrivers: Both flathead and Phillips head screwdrivers for various tasks.

- Wire Brush: To remove rust and debris from the tank’s surface.

- Sandpaper or Emery Cloth: For smoothing rough surfaces and preparing them for repair.

- Welding Equipment: If you’re skilled in welding, you may need equipment for certain repairs.

- Air Compressor: To test the repaired tank for leaks and functionality.

Materials:

- Replacement Parts: Depending on the damage, you may need to acquire new valves, fittings, or other components.

- Tank Patch Kit: These kits often include epoxy putty or fiberglass patches for sealing small leaks or cracks.

- Anti-Corrosion Paint: Apply this paint to the repaired areas to prevent future corrosion and protect the tank.

- Thread Sealant: For ensuring a secure seal on threaded connections.

- Cleaning Solvent: To thoroughly clean the tank’s surface before applying patches or performing repairs.

- Welding Rods (if applicable): If welding is necessary, ensure appropriate welding rods compatible with the tank material.

How To Air Compressor Tank Repair

The air compressor tank is a crucial component of any compressed air system. Over time, the tank can develop leaks or rust, reducing performance and potential safety hazards. Repairing the tank is essential to maintain the efficiency and safety of the air compressor. Regular inspection and maintenance of the tank can prevent small issues from turning into major problems.

Timely repairs can help avoid costly replacements and ensure the compressor is functioning at its optimal capacity, delivering clean, reliable air to the end users. Therefore, tank repair is crucial for the longevity and performance of the compressed air system. Here are some tips on how to air compressor tank repair.

Removing The Paint And Preparing The Area For Repair

Repairing an air compressor tank involves removing the paint and preparing the damaged area. Thoroughly strip away any existing paint using a paint stripper or sandpaper. This step ensures a clean surface for effective repair.

Eliminating debris and rust is essential for a successful repair process. A clean surface will allow better adhesion of the welding or epoxy putty used to fix the leak. Proper preparation is crucial as it sets the foundation for the subsequent steps, ultimately determining the repair’s effectiveness and longevity.

Welding The Leak Or Patching With Epoxy Putty

Repairing an air compressor tank involves addressing leaks through welding or epoxy putty application. If you have welding experience or seek professional help, welding is a reliable method for metal tanks. The welding process ensures a strong and permanent fix for significant leaks.

For small leaks or temporary solutions, epoxy putty designed for metal repairs is a suitable alternative. Ensure the epoxy putty is compatible with the tank material and follows the manufacturer’s instructions for application. A well-executed repair at this stage prevents further air leakage and ensures the tank’s safety and functionality.

Sanding And Smoothing The Repaired Area

After welding or applying epoxy putty to the air compressor tank, sanding and smoothing the repaired area is the next step. Use sandpaper to achieve a level surface, removing rough edges or excess putty. This step is crucial for a seamless paint application and a visually appealing finish.

Sanding also helps ensure the repaired area blends well with the rest of the tank’s surface. A smooth and even surface reduces the chances of paint chipping or peeling over time, enhancing the overall durability and aesthetics of the repair.

Applying Primer And Paint To The Repaired Area

Once the compressor tank repair is smooth and prepped, the repaired area requires proper priming and painting. Apply a primer layer for metal surfaces to promote paint adhesion and prevent corrosion. Allow the primer to dry completely before proceeding with the paint application.

Select a paint that matches the original color of the tank for a seamless blend. Applying the paint evenly over the repaired area will restore the tank’s appearance and protect it from further rust and damage, extending the tank’s lifespan and usability.

Testing The Air Compressor Tank For Any Additional Leaks

After completing the repair and painting process on the air compressor tank, it is crucial to conduct a thorough leak test. Before returning the tank to regular use, fill it with compressed air and carefully inspect for any signs of air leakage. Ensure that the repaired area and its surroundings are airtight and free from any new leaks.

Detecting and addressing additional leaks at this stage prevents potential safety hazards and the need for further repairs. A successful leak test confirms the effectiveness of the repair, ensuring the air compressor tank operates safely and efficiently.

Common Air Compressor Tank Problems

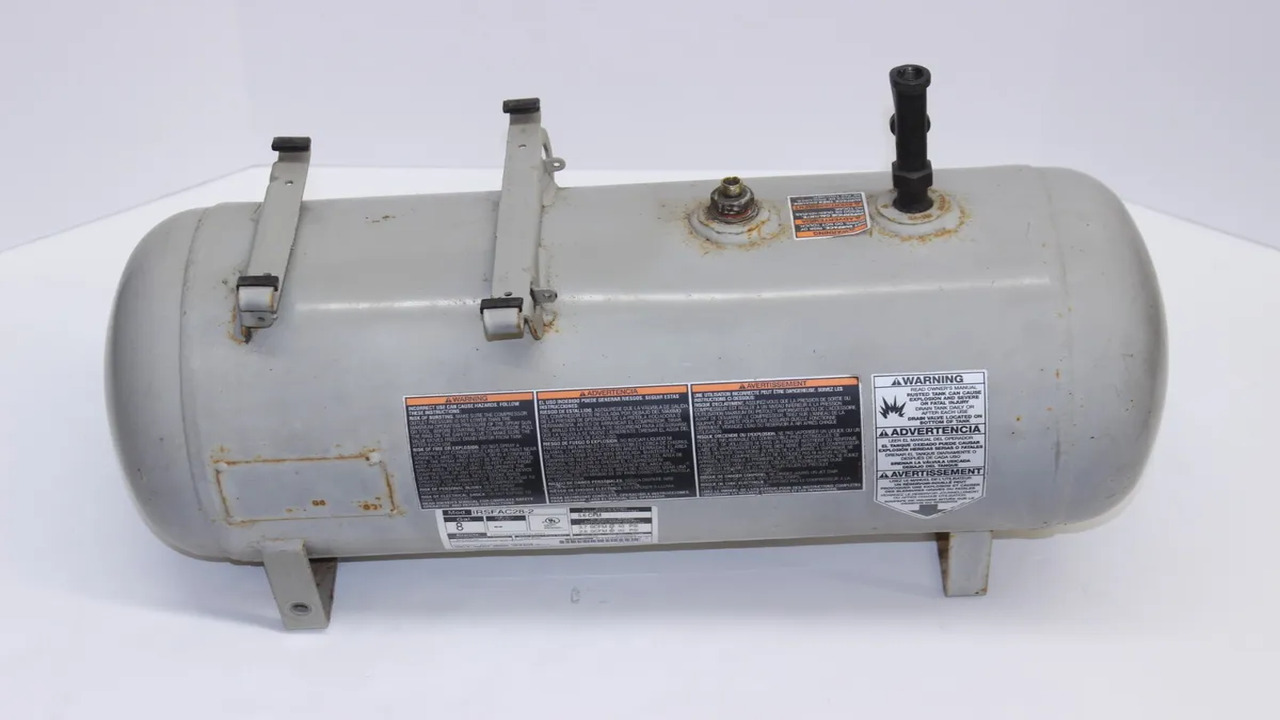

Air compressor tanks can experience several common problems that may necessitate repairs. One prevalent issue is rust and corrosion, especially in tanks that aren’t adequately maintained or exposed to moisture. Rust can weaken the tank and lead to leaks over time. Another problem is related to the tank’s pressure, where issues with the pressure switch, pressure relief valve, or pressure gauge can occur.

Motor problems are also common, resulting from improper lubrication or wear and tear. Regular maintenance, including proper condensation drainage and thorough inspections, can help identify and address these problems early, avoiding costly repairs.

Cost Of Compressor Tank Repair

The cost of compressor tank repair can vary depending on several factors. The extent of the damage and the type of repair required play a significant role in determining the cost. Welding, especially if performed by a professional, can be more expensive than epoxy putty. Additionally, the material of the tank and its size can influence the overall cost.

Minor repairs might be relatively affordable, while extensive damage may lead to higher expenses. To avoid costly repairs, regular maintenance is key, as it can prevent severe issues from developing and ensure the longevity of the air compressor tank.

Diagnosing Problems With An Air Compressor Tank

Air compressors are indispensable in many industries, providing a power source for various pneumatic tools and equipment. However, air compressor tanks, like any mechanical device, can develop problems over time. Diagnosing these issues is essential to ensure the proper functioning of your compressor and prevent costly downtime.

One of the most common problems with air compressor tanks is leaks. Leaks can occur in various places, including valves, fittings, and hoses. To diagnose a leak, you should first check all the connections and fittings for signs of damage or wear.

Another common problem with air compressor tanks is rust or corrosion. Over time, the inside of the tank can become corroded due to moisture and condensation. To diagnose this problem, you should inspect the tank for any signs of rust or corrosion. If you find any rust or corrosion, drain the compressor and remove any loose rust or debris. Finally, air compressor tanks can also experience pressure problems.

If the compressor is not producing enough pressure, you may need to check the pressure switch or replace the pressure regulator. If the compressor produces too much pressure, you may need to adjust the pressure relief valve or replace the pressure switch.

Maintenance Tips For Air Compressor Tanks

Proper maintenance is essential to keep air compressor tanks in optimal condition and prevent the need for frequent repairs. Regularly drain accumulated water and condensation from the tank to prevent corrosion. Keep the tank clean and free from debris to avoid potential damage. Inspect the tank for signs of rust or corrosion and address any issues promptly.

Ensure the compressor operates within the recommended pressure range and is correctly lubricated. Regular inspections can help identify potential problems early on, allowing for timely repairs and preventing costly breakdowns. Following these maintenance tips will extend the life of the air compressor tank and ensure safe and efficient operation.

Conclusion

Air compressor tank repair is a critical aspect of maintaining the functionality and safety of an air compressor system. The specificity of the repair process is paramount to ensuring that the repair is successful and that the repaired tank can withstand the high-pressure demands of the system. The importance of compressor tank repair cannot be overstated, as a damaged tank could lead to catastrophic failure and potential harm to both personnel and equipment.

The successful repair of the air compressor tank results in a safe and efficient system that can perform to its maximum potential without the risk of malfunction or failure. In the end, prioritizing the repair of a damaged air compressor tank can save time and money and prevent dangerous accidents.

FAQs

[rank_math_rich_snippet id=”s-14baa622-7cec-45ab-a517-07ec7d589634″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.