The functionality of a household and having a reliable source of gas is essential. From heating water for showers to preparing delicious meals on a gas stove, the uses for gas appliances are endless.

However, for these appliances to work efficiently, a proper connection to an existing gas line is crucial. This is where the importance of a connection between a water heater and a gas stove comes into play. Whether you are installing these appliances for the first time or upgrading to a newer model, knowing how to connect them to your existing gas line properly is essential.

Here, we will discuss the necessary steps and materials needed for a successful connection, including the use of black pipe and a metal cutting blade. And we will discuss how to tee off an existing gas line.

Tools Needed For Teeing Of An Existing Gas Line

When teeing off an existing gas line, it is essential to have the right tools to ensure a safe and efficient connection. Below are these tools readily available. You can tee off an existing gas line with confidence, knowing that you have taken the necessary precautions to ensure a safe and reliable connection. Here are the key tools needed for this process:

- Pipe Cutter

- Pipe Wrench

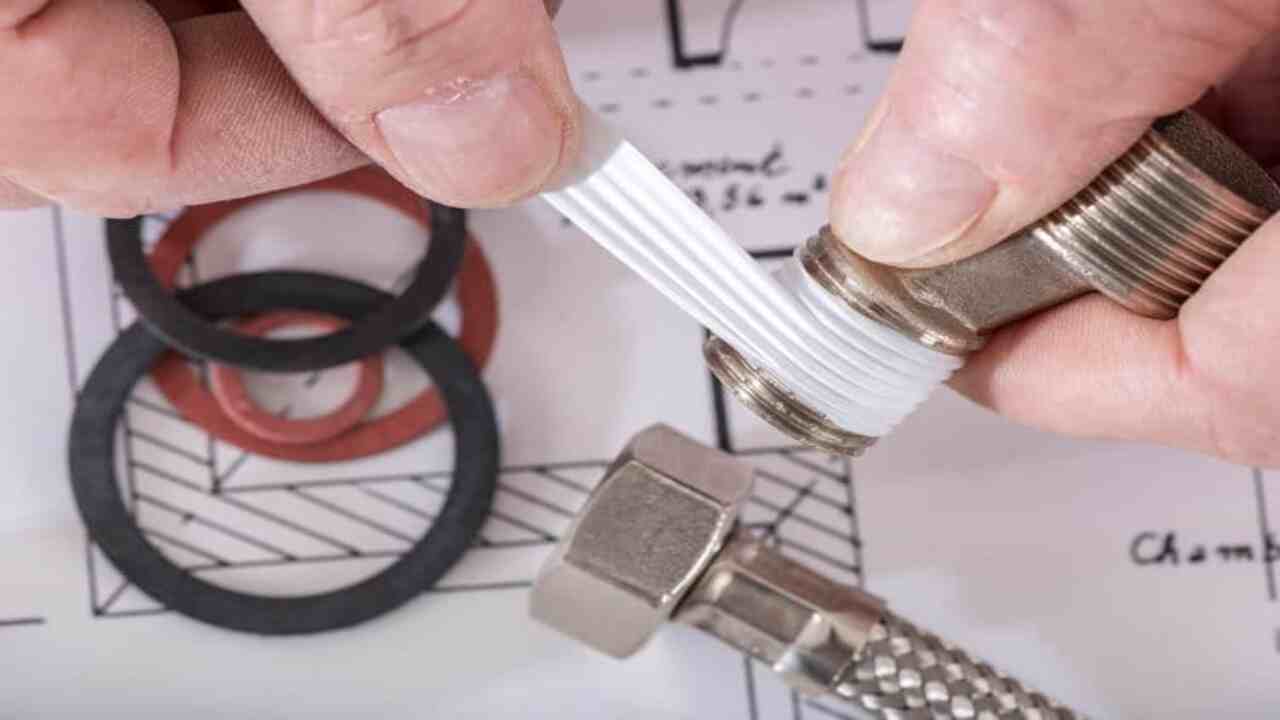

- Teflon Tape

- Thread Sealant

- Pressure Gauge

8 Steps To Tee Off An Existing Gas Line

When teeing off an existing gas line, safety and efficiency should always be top priorities. There are a few reasons why it’s important to tee off an existing gas line safely and efficiently. First and foremost, safety is key when dealing with gas lines. Additionally, by installing the tee efficiently, you can minimize the disruption and downtime for your gas system. Here are 8 steps to tee off the existing gas line.

1.Preparing The Area

Before teeing off an existing gas line, it is important to prepare the area and gather the necessary tools properly. Start by turning off the gas supply using the shutoff valve. This will help prevent any gas leaks or accidents during the process.

Next, ensure you have a pipe-cutting wrench on hand to cut into the existing gas line safely. It is crucial to follow all safety guidelines and regulations when working with gas lines to ensure the task is completed safely and efficiently.

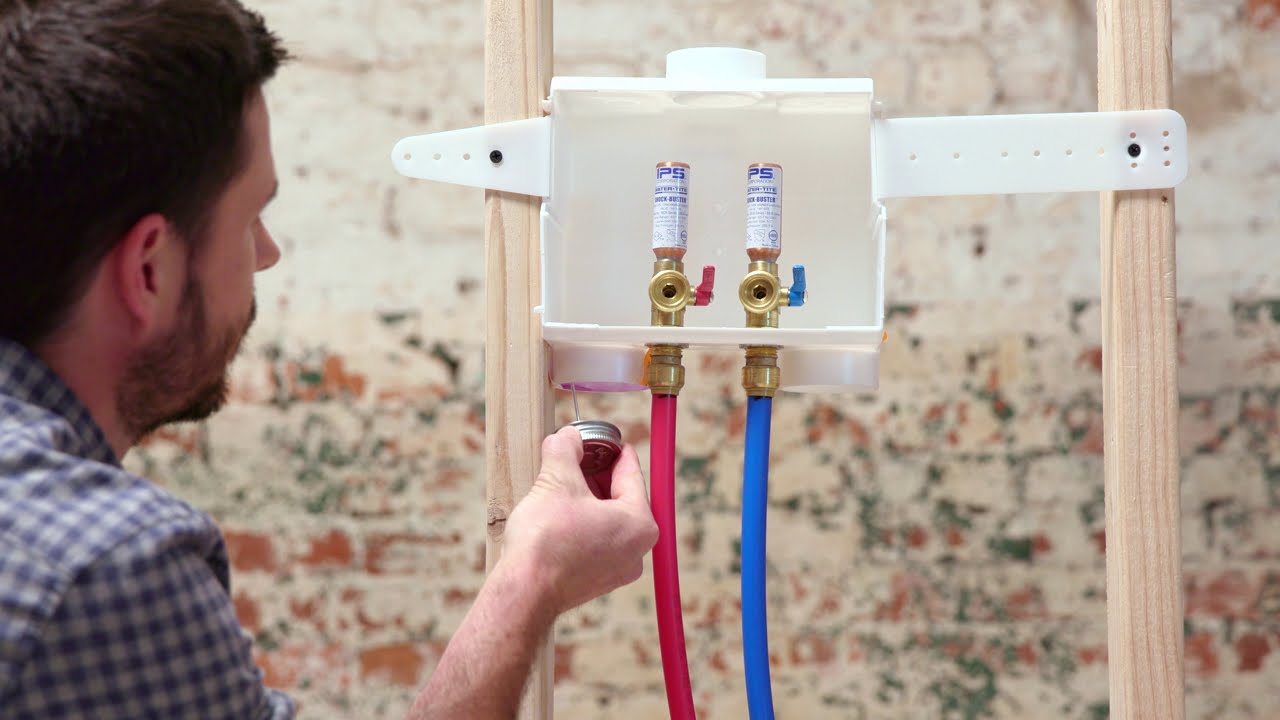

2.Connecting The Lines

When teeing off an existing gas line, it is crucial to prioritize safety and efficiency. This task should only be undertaken by a licensed professional who has the necessary expertise and training. Connecting the lines requires careful planning and precise execution to ensure that there are no leaks or other potential hazards.

By enlisting the services of a licensed professional, you can have peace of mind knowing that the job will be done correctly and in compliance with all relevant safety regulations.

3.Setting Up The Tee And Hose End Device

It is important to do so safely and efficiently. To set up the tee and hose end device, you will need a space piece of pipe that fits securely into the existing gas line. The tee should be installed using proper fittings and connections to ensure a tight seal.

It is also important to consider the type of device you will be connecting, such as a tankless water heater, as this may require additional steps or considerations. Always follow manufacturer instructions and consult with a professional if you are unsure about any aspect of the installation process.

4.Checking For Leaks

Whenever any renovation or repair work goes on, it’s important to prevent gas leaks. Shutting off the main gas line before starting work is a good way to ensure safety. Then, use a pressure meter to check for leaks and patch them up as needed. Be patient and take your time – this task isn’t easy but worth it in the long run.

5.Laying Out The Lines

When repairing or laying new gas lines, always use a spark-proof tool and avoid any contact with the gas lines themselves. Ensure you wear all the safety gear required, including a face mask and gloves.

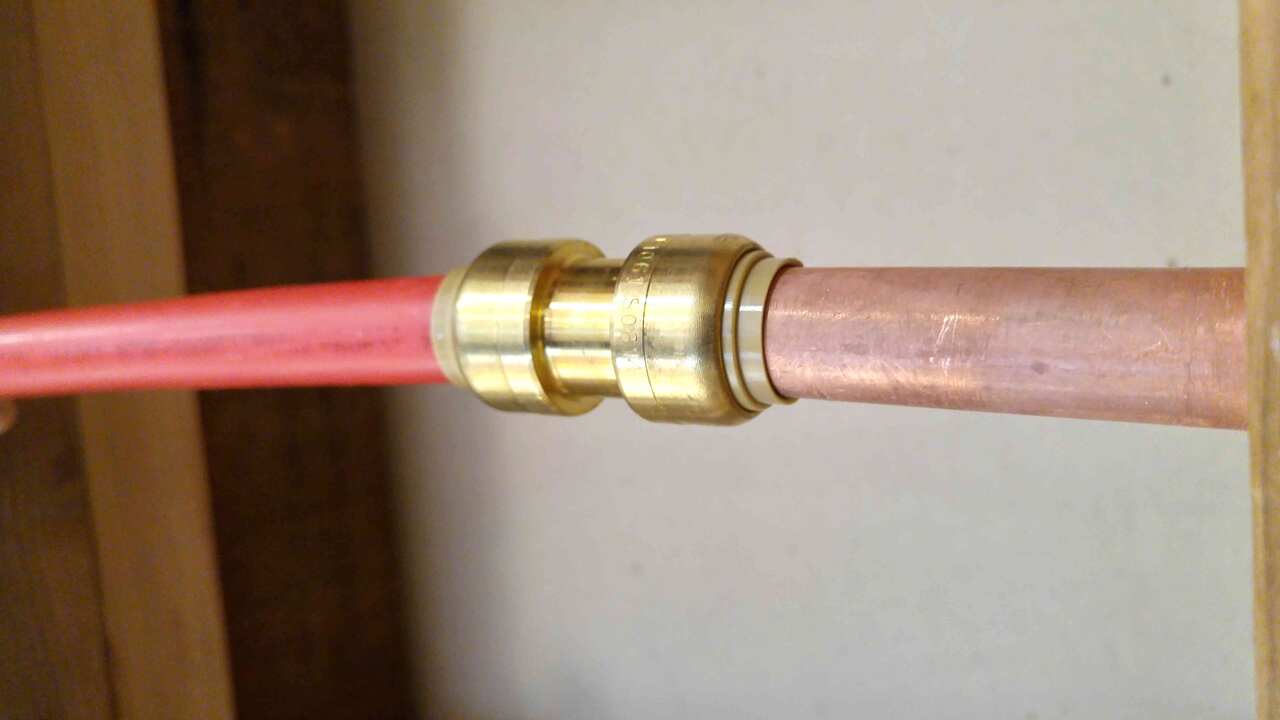

Tee off one joint at a time and wait for the gas to escape before proceeding to the next. If in doubt, call an experienced professional. Lay out the new gas line. This involves determining the location of the tee fitting, measuring the distance to the new appliance, and calculating the appropriate size of the new line. Once you have a plan, you must shut off the gas supply and depressurize the existing line.

This can be done by turning off the main gas valve and allowing the line to sit for a few minutes. Then, you can use a pipe cutter to cut into the existing line at the location of the tee fitting.

6.Marking The Line Of Play

Once the lines are laid out and ready to tee off, it’s important to mark where they intersect. This way, you can reconnect them if something goes wrong easily. Use a pipe clamp or a wire wheel hanger to make the markings. Be sure not to damage pipes during this process; use strong but gentle tools instead. Mark the line of play.

This means identifying where the gas line is so you can work around it without disturbing it. You can use various tools to mark the line, such as spray paint or flags. It is important to be thorough when marking the line so that you do not accidentally hit or damage the gas line.

7.Installing Tee Blocks Or Washers

When teeing off an existing gas line, installing Tee Blocks or Washers is the safest and most efficient way to go about it. Always use a safe gauge to ensure the blocks or washers are properly sized before installation.

Ensure to follow installation instructions provided by the Tee Blocks/Washers supplier, as improper measures may lead to dangerous accidents. Once installed, test your gas line for leaks before using them.

8.Making Sure The System Is Operational

Before starting any work on the gas line, verifying that the system is operational is always important. You can do this by using a gas detector or checking for leaks. If there are any problems with the system, take all necessary precautions and call for help as soon as possible!

When working with natural gas, it’s essential to stand off the line in a controlled manner to avoid injuring yourself or anyone else nearby. Accidents happen fast, and uncontrolled work could result in serious injury or even death.

Why Would You Want To Tee Off An Existing Gas Line?

When working with gas lines, safety should always be the top priority. Therefore, intentionally teeing off an existing gas line should only be done under specific circumstances and with the appropriate precautions in place. Here are a few reasons why someone might consider teeing off an existing gas line:

- Easy connection for additional appliances

- Cost-effective alternative to installing a new gas line

- Convenient for expanding gas service in a building or property

- Allows for efficient use of existing infrastructure

- Provides flexibility for future gas needs or upgrades

Choosing The Right Material For Gas Line Taping

Taping a gas line can be risky, but taking the right precautions is important to ensure a safe and successful job. Before you start, assess the situation and determine if it’s safe to tape the line. If it is, use a special type of caulking called E-coat to seal any gaps or tears in the pipe.

When it comes to gas line taping, there are a few things you need to consider. The first is the material that you’re using. This will depend on the type of gas line you’re working with and the environment in which you’ll tap it. Some of the most common materials used for gas line taping are:

a) Polyurethane Tape

This type of tape is ideal for humid or wet environments, as it has high water resistance. It’s also easy to remove and doesn’t leave any residue behind. Polyurethane tape is a popular choice for many professionals regarding gas line taping.

This type of tape is popular for its durability and resistance to corrosion, making it ideal for use in harsh environments. It can also withstand extreme temperatures and pressures, making it a reliable option for gas line applications.

b) PVC Pipe Tape

This type of tape is a good choice for outside gas lines, as it’s weatherproof and resistant to chemicals and oils. It also has a high durability rating, handling repeated use. When it comes to gas line taping, choosing the right material is crucial for ensuring safety and preventing leaks.

One option is PVC pipe tape, designed specifically for PVC pipes commonly used in gas lines. This type of tape is resistant to moisture and chemicals, making it a durable choice for protecting gas lines from corrosion and wear over time.

c) Vinyl Tape

This is a popular indoor use because it’s resistant to dirt, moisture, and oil. It also has good tear strength and can last up to six months without fading or coming off. When it comes to gas line taping, choosing the right material is crucial for ensuring safety and preventing leaks.

One popular option is vinyl tape, which is highly effective and easy to work with. Vinyl tape is water, oil, and chemical resistant, making it ideal for harsh environments.

d) Silicone Adhesive

This type of adhesive is good for inside gas lines, as it’s water resistant and has a high heat tolerance. It also comes in a range of colours to match your pipe. When choosing the right material for gas line taping, silicone adhesive is a popular option.

This type of adhesive is resistant to extreme temperatures and can withstand exposure to various chemicals and solvents. It also has excellent sealing properties, which makes it an ideal choice for gas line applications.

How Much Does It Cost To Tee Off A Gas Line?

The cost of teeing off a gas line can vary depending on several factors, including the complexity of the project and the materials needed. Generally, you can expect to spend between $150 to $300 for the fittings, including a gas cock and pipe joint. It is important to use proper gas fittings and equipment when teeing off a gas line to ensure safety.

Additionally, it may be necessary to cut through the existing gas line, which requires a metal blade or specialized cutting tool. To get an accurate estimate for your specific project, we recommend consulting with a professional plumber or gas line specialist.

How Do You Cap Off An Existing Gas Line?

When capping off an existing gas line, there are a few important steps to follow. First, you need to locate the gas pipe that needs to be capped. This pipe is typically connected to an electric stove or other gas-powered appliance.

Next, you will need to gather the necessary tools and materials, including a cap fitting and a wrench. Before proceeding, it is crucial to ensure the gas supply to the line is turned off. Once the gas is shut off, you can carefully disconnect the gas line from the appliance.

To cap off the line, you will need to insert the cap fitting onto the end of the gas pipe and tighten it securely using the wrench. It is always recommended to consult a professional gas line installer to ensure proper installation and safety. By following these steps and taking necessary precautions, you can cap off an existing gas line effectively and safely.

Is It Easy To Tee Off An Existing Gas Line?

Teeing off an existing gas line can be a complex task that requires careful planning and attention to detail. We do not recommend that inexperienced individuals attempt this task on their own, as it involves working with potentially dangerous gas vapours.

To ensure a safe and successful installation, it is advised to seek the advice of a professional plumber or gas technician who has the necessary knowledge and expertise. Additionally, proper sealing of connections is crucial to prevent gas leaks. We recommend using a joint compound or pipe dope specifically designed for gas lines to ensure a secure and leak-free connection.

Conclusion

To sum up, if you have an existing gas line in your house, it is very important to follow the above steps to tee off An Existing Gas Line. This way, you can be sure there won’t be any hazards due to gas leaks. Teeing off an existing gas line can be tricky and requires careful planning and execution.

Following all safety protocols and guidelines is important to ensure the job is done correctly and without incident. If you are not confident in your ability to tee off a gas line alone, hiring a professional with the expertise and experience needed to get the job done right is always best.

By taking the time to carefully evaluate your options and choose the right contractor for the job, you can ensure that your gas line teeing project is completed safely and successfully.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-8814c87c-c356-415c-a48d-e479901ad30a”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.