When installing a plywood subfloor, choosing the right screws is crucial for a sturdy and long-lasting foundation. It’s easy to be overwhelmed by the various screws available on the market, each with its own features and benefits.

However, selecting the wrong screws can lead to an unstable subfloor prone to squeaking. This is why it’s important to understand the key factors when choosing screws for your plywood subfloor.

Here, we’ll share expert tips on how to select the right screws for plywood subfloor. We’ll cover the various types of screws available, the size and length of screws needed, and the importance of using screws with a specific thread type.

How To Choose The Right Screws For Plywood Subfloor

When choosing the right screws for the plywood subfloor, there are a few key factors to consider. First, you’ll want to consider the type of plywood and subfloor you’re working with. This will help determine the appropriate screw length and diameter. Additionally, it’s important to use screws specifically designed for subfloor installation, such as deck screws or construction screws.

Look for screws with a coarse thread and sharp points to ensure a secure and tight connection. Consider using screws with a corrosion-resistant coating if you expose the subfloor to moisture. Pre-drilling holes slightly smaller than the screw diameter can also help prevent plywood splitting. For efficient and precise screw installation, using a power drill or impact driver is recommended.

Understanding The Types Of Screws Available In The Market

When it comes to plywood subfloor installation, there are several types of screws available in the market. People commonly use wood screws, drywall screws, and deck screws. Wood screws, with their sharp point and coarse threads, provide a good grip in wood and are the go-to choice for plywood subfloors.

On the other hand, drywall screws, designed for use in drywall, are not ideal for plywood subfloors due to their fine thread. Deck screws, featuring a corrosion-resistant coating, are a great option for outdoor plywood subfloors, protecting against moisture damage. When choosing screws for plywood subfloor installation, it’s important to consider the length and gauge of the screw to ensure proper penetration and support.

Factors To Consider When Choosing Screws Subfloor

When choosing screws for your plywood subfloor, there are several factors to consider. First, you need to ensure that the length of the screw is adequate to penetrate through the plywood subfloor and into the underlying joists or subflooring material.

Additionally, the diameter of the screw should be appropriate for the thickness of the plywood subfloor to provide sufficient holding power without splitting the wood. It is also important to select screws made from a corrosion-resistant material, such as stainless steel, to prevent rust and deterioration over time.

Contractors commonly use coarse-threaded screws for plywood because they offer a better grip and can pull the subfloor tightly to the joists. Moreover, opt for flat-head or countersunk screws that can be easily countersunk into the wood surface, resulting in a smooth and level finish. Finally, following the manufacturer’s guidelines for recommended screw spacing is crucial to ensure proper support and stability of the plywood subfloor.

Screw Size And Length For Plywood Subfloor

When choosing the right screws for a plywood subfloor, there are a few factors to consider. The most important factor is the size and length of the screws. For plywood subfloors, it is recommended to use #8 or #10 screws with a length of 1 ⅝ inches or longer.

These screws provide enough strength and stability to fasten the subfloor to the joists securely. Additionally, it is important to choose screws designed specifically for use with plywood. Will have the necessary threading and grip to hold the subfloor in place. By selecting the appropriate screw size and length. You can ensure a secure, durable plywood subfloor that withstands everyday wear and tear.

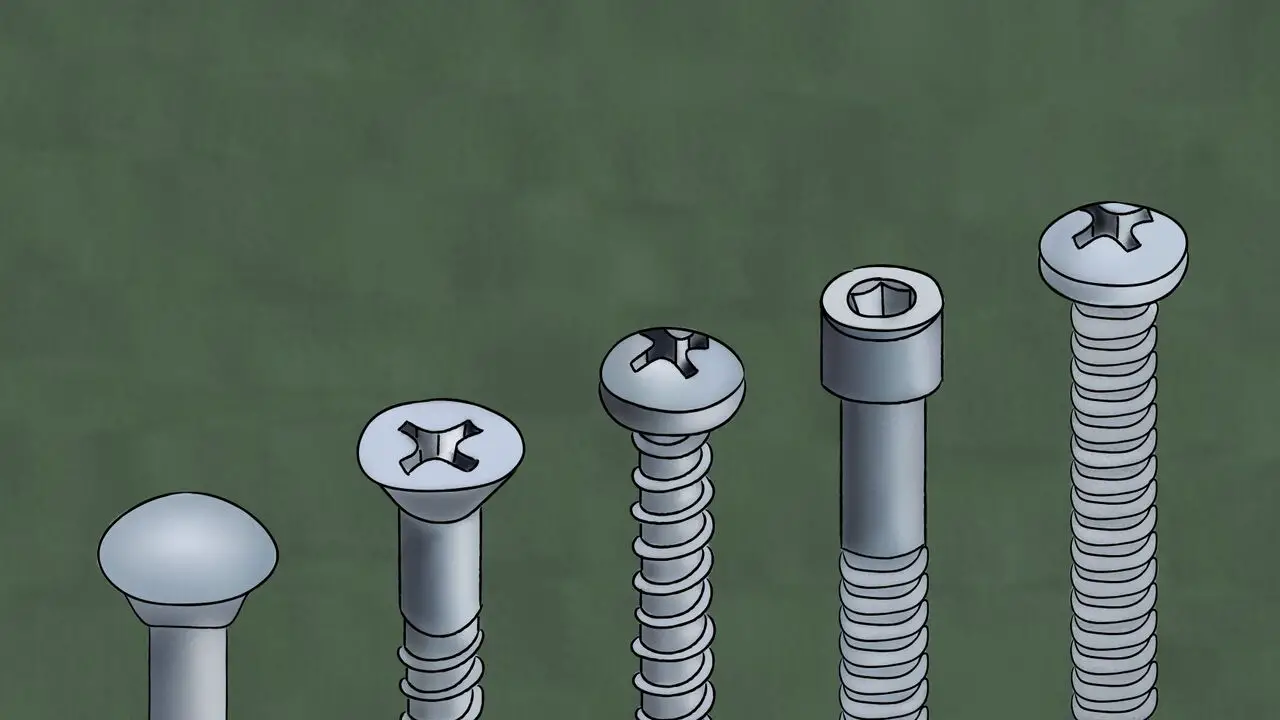

Screw Head Types For Plywood Subfloor

When choosing screws for a plywood subfloor, a few options exist. The most common type of screw used for this purpose is a deck screw. These screws have a sharp point and a wide, flat head that helps to prevent the screw from pulling through the plywood.

You can use an all-purpose construction screw for subfloor installation, giving you another option. These screws typically have a smaller head than deck screws but still, provide good holding power. Choosing screws long enough to penetrate the plywood and the underlying joists or subflooring material is important.

Additionally, using screws with a corrosion-resistant coating can help to prevent rust and increase the longevity of your subfloor. Overall, selecting the right type of screw for your plywood subfloor is essential for ensuring a secure and stable flooring installation.

Screw Coatings And Finishes For Plywood Subfloor

When selecting screws for a plywood subfloor, it’s crucial to consider the type of coating or finish applied to the screws. Coated options, such as galvanized or zinc-plated screws, offer extra protection against rust and corrosion. For areas with high moisture or humidity levels, stainless steel screws are an excellent choice due to their resistance to rust and corrosion.

Additionally, certain screws feature a self-drilling tip, simplifying and expediting installation. To ensure proper installation, choose screws with the appropriate length and diameter based on the subfloor’s thickness and the type of flooring you intend to install.

Common Mistakes To Avoid When Choosing And Installing Screws For The Plywood Subfloor

When selecting screws for your plywood subfloor, avoiding common mistakes is essential. First and foremost, always use screws specifically designed for subfloor installation, such as subfloor screws or deck screws. Avoid using drywall screws, as they cannot hold plywood subflooring securely. Additionally, consider the length of the screws.

They should be long enough to penetrate the plywood and the underlying joists or floor framing for maximum stability. To prevent rust and corrosion, especially in areas with high moisture levels, opt for coated or galvanized screws. You need to use a screw gun or drill with a clutch to drive the screws flush with the plywood surface without over-tightening and damaging the wood.

Conclusion

A screw for a plywood subfloor is a type of screw that is specifically designed for use in plywood subfloors and other construction applications that involve plywood or a similar material. Choosing the right screws for your plywood subfloor ensures a sturdy and long-lasting foundation.

From understanding the types of screws available in the market to considering factors like size, length, head types, and coatings, there are several expert tips to keep in mind. By following these tips and avoiding common mistakes, you can ensure a successful installation that will withstand the test of time. We have provided bulk information for screws for plywood subfloor and hope our information was helpful from your perspective.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-6cd045e3-079a-432e-9f08-c22f15048de3″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.